- Home

- Products

- Materials

- Polyurethane New Materials

- PU Elastomer Material

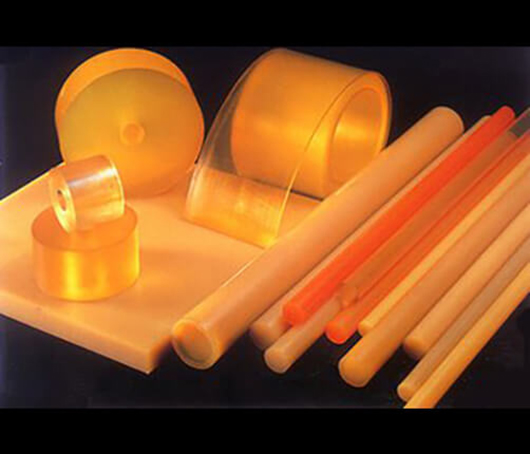

Polyurethane (PU) elastomers are polymeric materials based on diisocyanates, polyols, and in some cases on chain extenders when reacted to produce synthetic materials with elastomeric properties.

-

Polyurethane Elastomer Roller Material

This polyurethane elastomer roller material is specifically designed for producing high-performance elastomer rollers. It features excellent wear resistance, oil resistance, tear resistance, and resilience, making it widely applicable in industries such as steel, photovoltaic, and printing.

Details -

Polyurethane Elastomer Raw Material for Mining Screen Panels

This polyurethane elastomer raw material is specifically developed for producing high-performance mining screen panels, providing strong assurance for your screening operations.

Product Features:

● Exceptional Wear Resistance, Longer Lifespan: Designed for harsh mining conditions, it offers superior wear resistance, with a lifespan 3-5 times that of ordinary rubber screen panels, significantly reducing replacement frequency and maintenance costs.

Details -

Polyurethane Elastomer Material for Skate Wheels

This polyurethane elastomer material is specifically designed for manufacturing high-performance skate wheels, delivering an exceptional skating experience.

Product Features:

● Outstanding Wear Resistance: Compared to traditional rubber materials, polyurethane elastomer offers superior wear resistance, effectively extending the lifespan of the wheels and allowing you to skate longer.

Details -

Polyester Polyol

Dyc® series products are the polyester polyols synthetized with aliphatic diprotic acids, possessing the performance of narrow distribution of molecular weight, low chrominance, low moisture contentetc, which can be used for polyurethane materials, such as elastomers, coatings, adhesives, and microcellular elastomer etc.

Among all the products, Dyc® PST series are the polyester polyols specially used for solvent-resistance polyurethane elastomers. Synthetized with the Dyc® PST series polyester polyol, the solvent resistance of polyurethane is two times better than the common polyurethane.

Details -

Polyurethane Prepolymer

Strodu® series products are polyurethane casting materials, including polyurethane prepolymers and system products. Prepolymers include toluene diisocyanate (TDI) terminated prepolymers based on polyester polyol, TDI terminated prepolymers based on polyether polyol, diphenyl methane diisocyanate (MDI) terminated prepolymers based on polyester polyol, MDI terminated prepolymers based on polyether polyol, and special prepolymers, which can be widely used in rubber roller, rubber wheels, seals, sieve plates and other miscellaneous pieces of polyurethane products.

Details -

Polyurethane Casting Materials

Strodu® series PU system materials include TDI terminated system products based on polyester polyol, TDI terminated system products based on polyether polyol, MDI terminated system products based on polyester polyol, MDI terminated system products based on polyether polyol, and microcellular system products.

Among those products, the solvent-resistance system products of TDI terminated system products based on polyester polyol possesses the performance of high strength, tear strength and elastic, oil resistance, high temperature-resistance, produced products can be processed easily etc.

Details -

Polyurethane Materials for Spraying Coatings

Strodu®SP series products mainly include continuous-spraying products and special repair materials. They can be widely used in abrasion protection, terrace project, water and corrosion-proof project of roof, railway bridges and roadbed etc., and can be operated whatever by elevation or plane. The special repair materials are easy to be operated, which is the ideal choices for spraying profiles and the small parts under the complicated working circumstances.

Details -

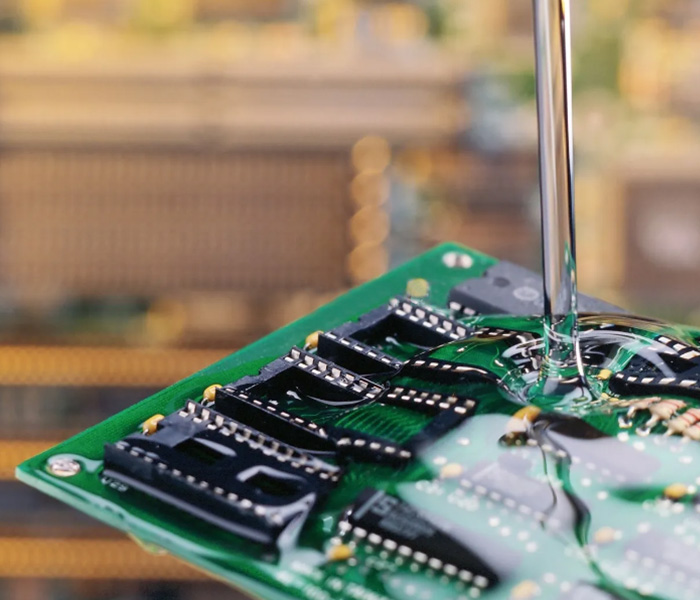

Encapsulating PU Materials

The encapsulating PU materials of Caselec® series with the properties of satisfied strength, high elastic, excellent hydrolysis resistance, heat resistance, mycotic resistance, acid-base resistance, cold and heat shock resistance, ultraviolet radiation resistance, environmental friendly, electrical insulation and flame retardant, perform excellent when bonded with metals such as steel, aluminum, copper and tin, rubbers, plastics, wood and other materials, and are the ideal sealing materials.

Details -

Light-curing Polyurethane Oligomer

Polyurethane acrylate as the oligomer of light-curing resin, can be used for UV coatings, printing ink and UV adhesives. Products of Hitec® series include high molecular weight series, low energy curing series, fast curing series, low viscosity series, self-repair series etc., with the performance of fast curing, low shrinkage, good adhesion and dispersion, can be used in the fields of 3C, automobile, wood processing, printing and so on.

Details

中文

中文 English

English Русский

Русский Español

Español Français

Français Português

Português العربية

العربية Deutsch

Deutsch 한국어

한국어 ภาษาไทย

ภาษาไทย Italiano

Italiano Tiếng Việt

Tiếng Việt Bahasa Indonesia

Bahasa Indonesia Malay

Malay Türkçe

Türkçe