● Outstanding Wear Resistance: Compared to traditional rubber materials, polyurethane elastomer offers superior wear resistance, effectively extending the service life of rollers and reducing replacement frequency and maintenance costs.

● Excellent Oil Resistance: It has good tolerance to oils and lubricants, making it suitable for various oily environments and ensuring stable roller performance.

● Superior Tear Resistance: High tear strength effectively prevents rollers from tearing and breaking during use, ensuring the continuity and stability of production processes.

● High Resilience: High resilience ensures that rollers can quickly regain their shape, maintaining good elasticity and cushioning properties, making them suitable for various high-precision processing and transmission applications.

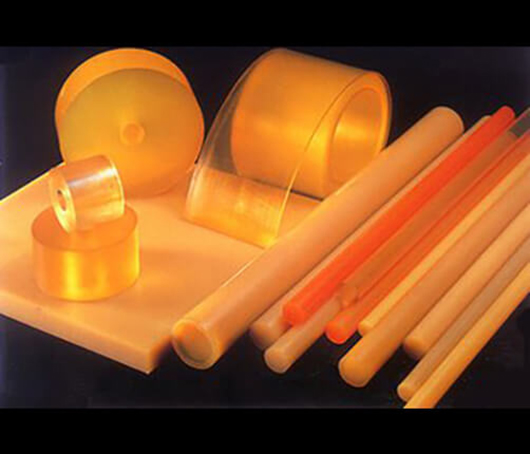

● Multiple Hardness Options: We offer polyurethane elastomer roller materials in various hardness grades to meet the needs of different application scenarios for hardness, elasticity, and wear resistance.

● Steel Industry: Used for conveyor rollers, straightening rollers, pinch rollers, etc., in equipment such as continuous casters and rolling mills.

● Photovoltaic Industry: Used for cleaning rollers, conveyor rollers, embossing rollers, etc., in the solar panel production process.

● Printing Industry: Used for ink rollers, water rollers, impression rollers, etc., in printing machines.

● Other Fields: Various elastomer rollers are also needed in industries such as papermaking, textiles, and packaging.

● Longer roller service life

● More stable production performance

● Lower maintenance costs and downtime

● Broader application fields

中文

中文 English

English Русский

Русский Español

Español Français

Français Português

Português العربية

العربية Deutsch

Deutsch 한국어

한국어 ภาษาไทย

ภาษาไทย Italiano

Italiano Tiếng Việt

Tiếng Việt Bahasa Indonesia

Bahasa Indonesia Malay

Malay Türkçe

Türkçe