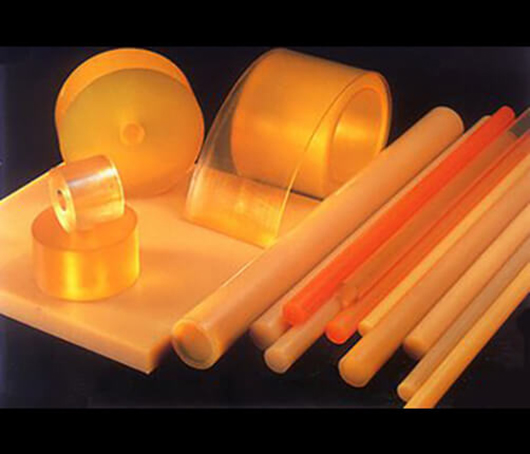

Strodu® series PU casting materials include TDI terminated system products based on polyester polyol, TDI terminated system products based on polyether polyol, MDI terminated system products based on polyester polyol, MDI terminated system products based on polyether polyol, and microcellular system products.

Among those products, the solvent-resistance system products of TDI terminated system products based on polyester polyol possesses the performance of high strength, tear strength and elastic, oil resistance, high temperature-resistance, produced products can be processed easily etc. the casting polyurethane materials with three components possess the performance of moderate viscosity, strength rising fast, adjustable hardness, high strength, tears trength, elastic and abrasion, low temperature resistance, good dynamic performance and high transparency, etc.; the system products of low-temperature-casting with properties of high strength, elastic, abrasion and transparency, hydrolysis resistance, low temperature resistance, bending resistance, and environment friendly etc.; microcellular system products possess good performance of low temperature molding, high mobility, dynamic fatigue property, low compression permanent deformation and products surface smooth etc.

In addition, customized polyurethane casting materials and application solutions for many industries are also available.

中文

中文 English

English Русский

Русский Español

Español Français

Français Português

Português العربية

العربية Deutsch

Deutsch 한국어

한국어 ภาษาไทย

ภาษาไทย Italiano

Italiano Tiếng Việt

Tiếng Việt Bahasa Indonesia

Bahasa Indonesia Malay

Malay Türkçe

Türkçe