HTPB / Hydroxyl-terminated polybutadiene CAS: 69102-90-5

Product details:

Chemical Name: Hydroxyl-terminated polybutadiene

Code: HTPB, HTPB-R45M

CAS: 69102-90-5

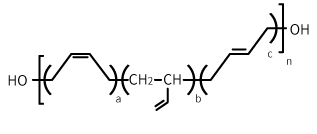

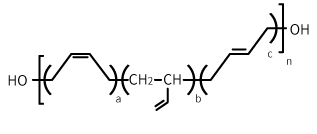

Formula:

Character: China Authorized Exporter / HTPB export licence

Standard: GB (Civil Grade) / GJB (Military Grade/ GJB 1327A-2003)

HTPB is a liquid remote claw polymer, the new liquid rubber. The properties vary because HTPB is a mixture rather than a pure compound, and it is manufactured to meet customers' specific requirements. A typical HTPB is R-45M with each end of the chain terminated with a hydroxyl [OH] group. (PS: we can do any versions of HTPB as customers request, and new design the HTPB with a single chain of hydroxyl -OH, Meanwhile, we can do hydrogenation of the HTPB).

It and chain extension agent, crosslinking agent in room temperature or high temperature reaction can generate 3D network structure of curing content.The curing content has excellent mechanical properties, especially good resistance to hydrolysis, acid and alkali resistant, wear resistance, low temperature resistance and excellent electrical insulation.

Polyurethanes prepared from HTPB can be engineered for specific physical properties; polyurethanes may be highly elastic or tough and rigid. Some products include: rigid foam insulation panels; durable elastomeric wheels and tires (used for roller coasters, escalators, skateboards, etc.); automotive suspension bushings; electrical potting compounds; high-performance adhesives; surface coatings and surface sealants; synthetic fibers (e.g., Spandex); carpet underlay; hard-plastic parts (e.g., for electronic instruments).

An important application of HTPB is in solid rocket propellant. It binds the oxidizing agent, fuel and other ingredients into a solid but elastic mass in most composite propellant systems. The cured polyurethane acts as a fuel in such mixtures. For example the propellant as "HTPB/AP/Al=12/68/20", which means, proportioned by mass, HTPB plus curative 12% (binder and fuel), ammonium perchlorate 68% (oxidizer), and aluminum powder 20% (fuel).

Similar propellants, often referred to as APCP (ammonium perchlorate composite propellant) are used in larger model rockets. A typical APCP produces 2–3 times the specific impulse of the black powder propellant used in most smaller rocket motors.

HTPB is also used as a hybrid rocket fuel.

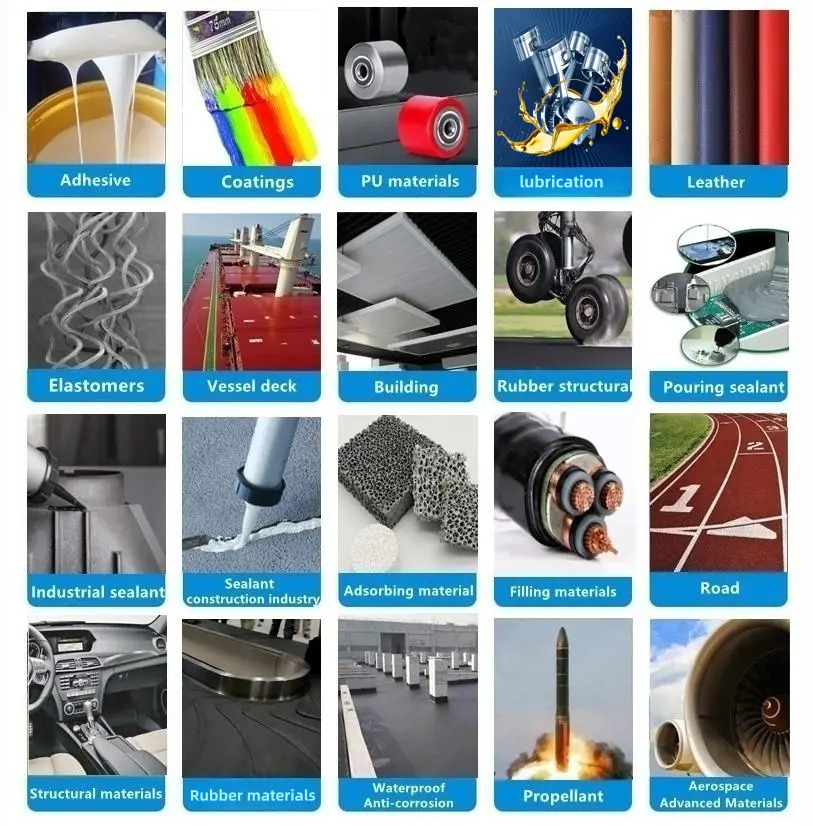

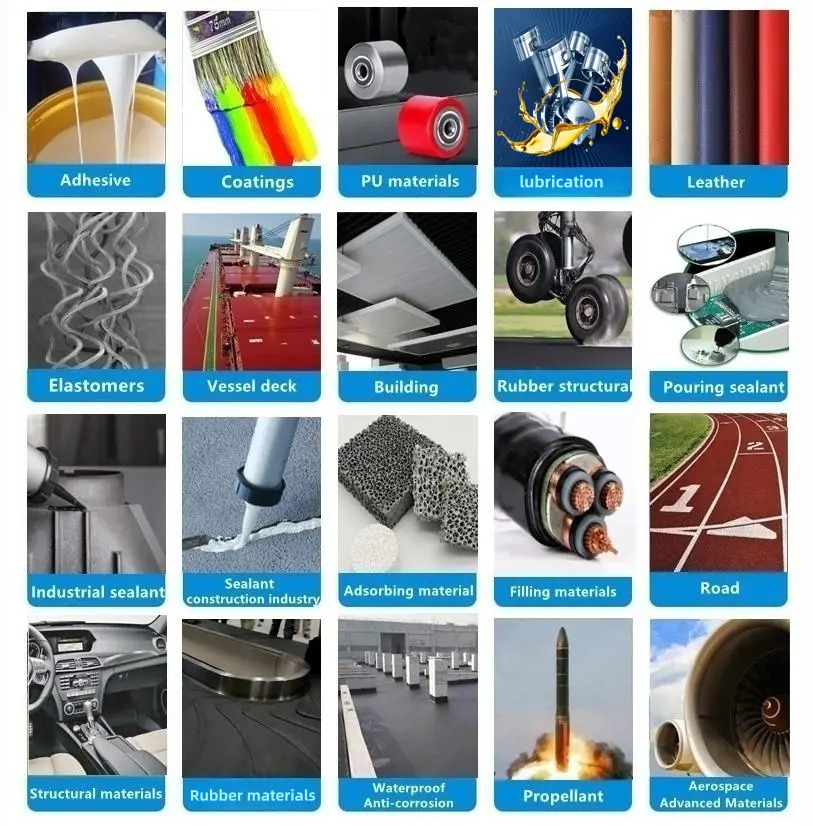

HTPB has good diaphaneity, low viscosity, ageing resistance, low temperature performance, Hydrolysis resistance, acid and alkali resistance, wear resistance and excellent electrical insulation properties and processing performance is good. HTPB can be used in:

- Adhesive

- Sealents

- Polymers

- Electrical insulation materials

- Waterproofing and corrosion protection materials

- Coating

- Polyurethane materials

- Rubber products

- Solid fuel

- Propellant

- Car and Planes tires of structural materials

- Hydroxyl-terminated polybutadiene propellant(HTPB+AP+Al)

- Aerospace, Rockets and Missile

- and so on many kinds of usage.

Packing:

Packed in 50kg/drum, 170kg/drum, The storage period is 1 year.

Safety instructions:

Storage should be at cool, dry and ventilate. The best condition is among -20 ~ 38℃. Shelf life of 12 months, if expire, still used if up to standard through retest. When transportation should avoid rain, sunlight. Don’t mix with strong oxidizer.

中文

中文 English

English Русский

Русский Español

Español Français

Français Português

Português العربية

العربية Deutsch

Deutsch 한국어

한국어 ภาษาไทย

ภาษาไทย Italiano

Italiano Tiếng Việt

Tiếng Việt Bahasa Indonesia

Bahasa Indonesia Malay

Malay Türkçe

Türkçe