Short Description:

Chemical Name: Polyurethane PU components

Components: blended polyether, isocynate

Chemical Name: Polyurethane PU components

Components: blended polyether, isocynate

Product Description

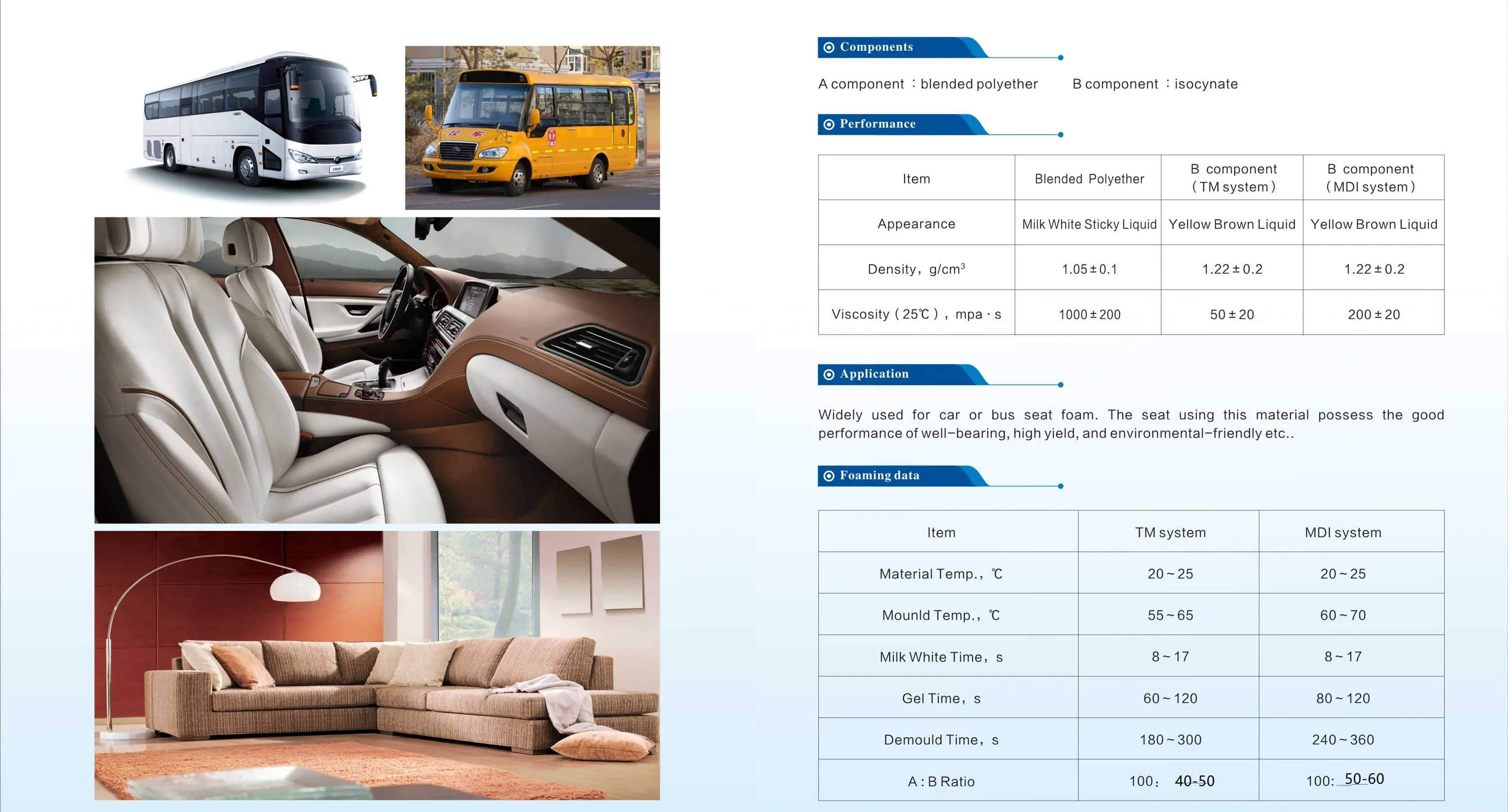

A component: blended polyether

B component: isocynate

Performance

|

Item

|

A component

Blended Polyether

|

B component (TM system) | Bcomponent (MDI system) |

|

Appearance

|

Milk white sticky liquid

|

Yellow brown liquid

|

Yellow brown liquid

|

|

Density, g/cm3

|

1.05±0.1

|

1.22±0.2

|

1.22±0.2

|

|

Viscosity(25℃), mPa·s

|

1000±200 |

50±20

|

200±20

|

Application

Widely used for window, glass encapsulation window sealing strip car, vehicle, automobile, while for car or bus seat foam, the seat using this material possess the good performance of well-bearing, high yield, and environment-friendly etc.....

Foaming data

|

Item

|

TM system

|

MDI system

|

|

Material temp., ℃

|

20 - 25

|

20 - 25

|

|

Mounld temp., ℃

|

55 - 65

|

60 - 70

|

|

Milk white time, s

|

8 - 17 | 8 - 17 |

|

Gel time, s

|

60 - 120 |

80 - 120

|

|

Demould time, s

|

180 - 300 | 240 - 360 |

|

A : B ratio

|

100 : 40-50

|

100 : 50-60

|